How to Make Graphene – Simple and Advanced Methods Explained

Graphene — a single layer of carbon atoms arranged in a honeycomb lattice — is one of the most extraordinary materials ever discovered. While commercial graphene requires advanced manufacturing techniques, it's also possible to produce small amounts of graphene using simple methods suitable for laboratories and even home experiments.

In this article, we'll explore both professional and DIY approaches to making graphene, including mechanical exfoliation, chemical vapor deposition, and electrochemical methods, while explaining the safety and quality considerations involved in each process.

1. Understanding the Basics of Graphene

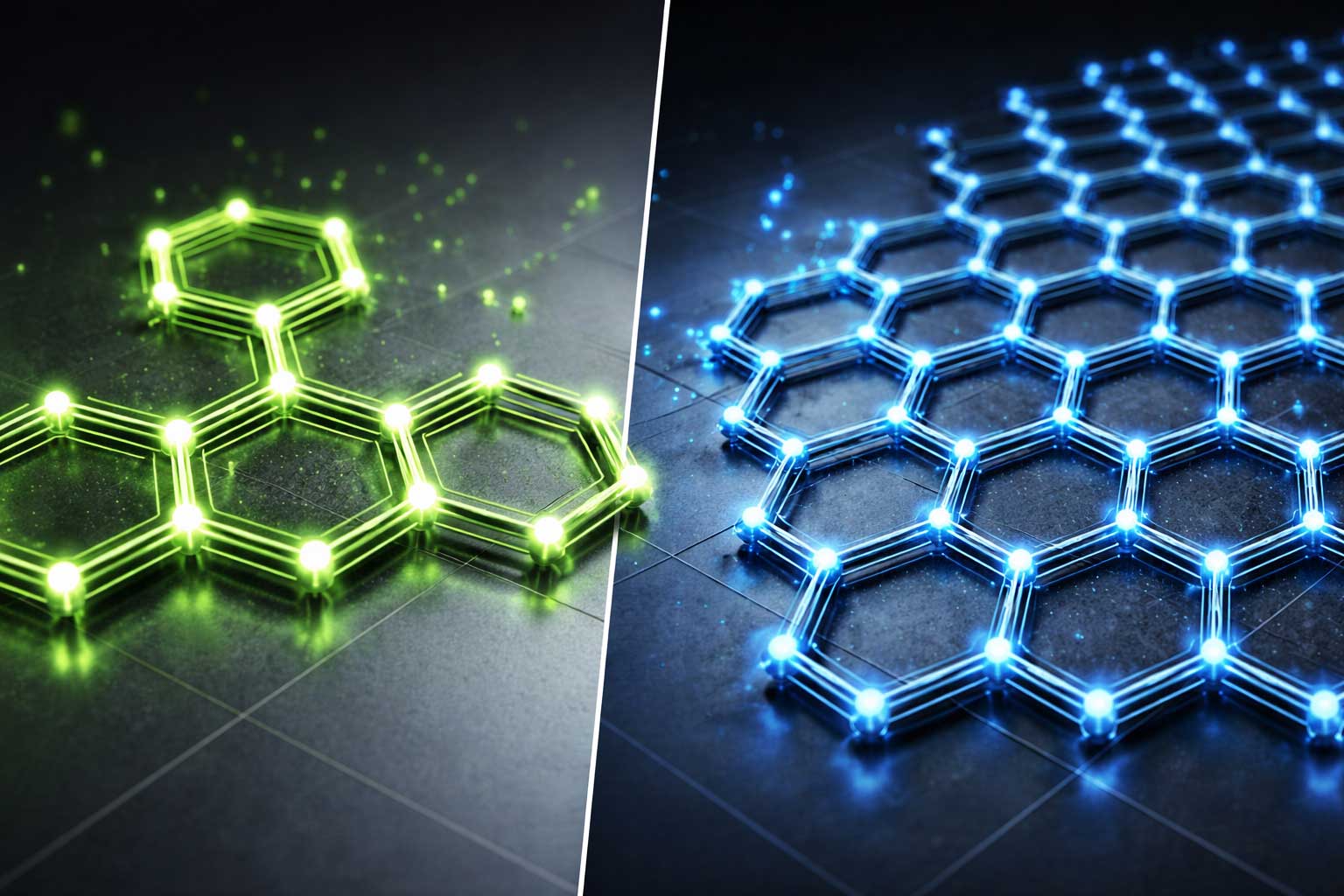

Graphene is a single atomic layer of graphite. Because graphite is composed of stacked graphene sheets, many production methods focus on separating or synthesizing these layers. The quality of graphene depends on how pure, defect-free, and uniform the final sheet is.

2. How to Make Graphene at Home (Educational Experiment)

For science students and enthusiasts, a simple "DIY graphene" method can demonstrate the concept of exfoliation. Although this won't produce industrial-grade graphene, it helps visualize the basic structure.

2.1 Materials Needed

- Pencil graphite (preferably soft, 6B or higher)

- Transparent adhesive tape

- Glass slide or silicon wafer

- Microscope (optional)

2.2 Procedure

- Use adhesive tape to peel a thin layer of graphite from the pencil lead.

- Fold and peel the tape repeatedly to thin the layer further.

- Press the tape onto the glass slide or substrate, then peel it off gently.

- Under a microscope, you may see translucent flakes — these are few-layer graphene sheets.

This is known as the mechanical exfoliation method — the same technique first used to discover graphene in 2004 by Geim and Novoselov at the University of Manchester.

3. Laboratory Methods for Making Graphene

Scientific and industrial processes allow for more precise control of graphene's quality, structure, and size.

3.1 Chemical Vapor Deposition (CVD)

The CVD method involves decomposing a carbon-rich gas (like methane) over a metal catalyst at high temperatures (around 1000°C). The carbon atoms arrange themselves into a single graphene layer on the metal surface, which can then be transferred onto other substrates.

- Produces high-quality, large-area graphene films.

- Used in electronics, sensors, and flexible displays.

3.2 Electrochemical Exfoliation

This technique uses electricity to separate graphene layers from graphite electrodes immersed in an electrolyte solution.

- Graphite is connected to a power source and exfoliated using ionic reactions.

- Produces graphene nanosheets efficiently at low cost.

- Environmentally friendly and scalable.

3.3 Chemical Reduction of Graphene Oxide (rGO)

In this process, graphite is first oxidized to form graphene oxide (GO), which is then reduced chemically to restore conductivity and structure.

- Uses mild reducing agents such as ascorbic acid (vitamin C) or hydrazine.

- Yields reduced graphene oxide (rGO), suitable for coatings and batteries.

3.4 Liquid-Phase Exfoliation

Graphite flakes are dispersed in a solvent and separated using ultrasonication or high-shear mixing.

- Ideal for producing bulk graphene powders and inks.

- Used in paints, coatings, and polymer composites.

4. Safety Precautions

While graphene itself is not inherently toxic, its nanoparticle form can be reactive and airborne. Always follow basic safety protocols when conducting experiments:

- Wear gloves, goggles, and a lab coat.

- Work in a well-ventilated area or under a fume hood.

- Dispose of chemical waste responsibly.

5. Industrial-Scale Graphene Manufacturing

Commercial graphene is produced using CVD reactors, roll-to-roll systems, and electrochemical exfoliation units. Companies are also exploring plasma-enhanced and eco-friendly synthesis routes to reduce energy use and waste output.

For more technical background, see our detailed post: How Is Graphene Made?

FAQ

Q1: Can you really make graphene at home?

Yes, using the adhesive tape method with pencil graphite, you can create microscopic graphene flakes for educational purposes. However, industrial-quality graphene requires advanced equipment.

Q2: What is the cheapest way to make graphene?

The liquid-phase exfoliation and electrochemical methods are among the most cost-effective and scalable options.

Q3: Can graphene be made from coal or carbon?

Yes. Researchers have successfully synthesized graphene from coal, biomass, and even waste carbon materials using thermal or plasma processes.

Q4: How much graphene can be produced from graphite?

One gram of graphite can yield several square meters of single-layer graphene under optimized conditions, depending on the method used.

Q5: What are the main challenges in making graphene?

Balancing quality, cost, and scalability remains the biggest challenge. Producing defect-free graphene on an industrial scale is complex but rapidly improving.