Graphene Uses: Real-World Applications (Commercial vs Experimental)

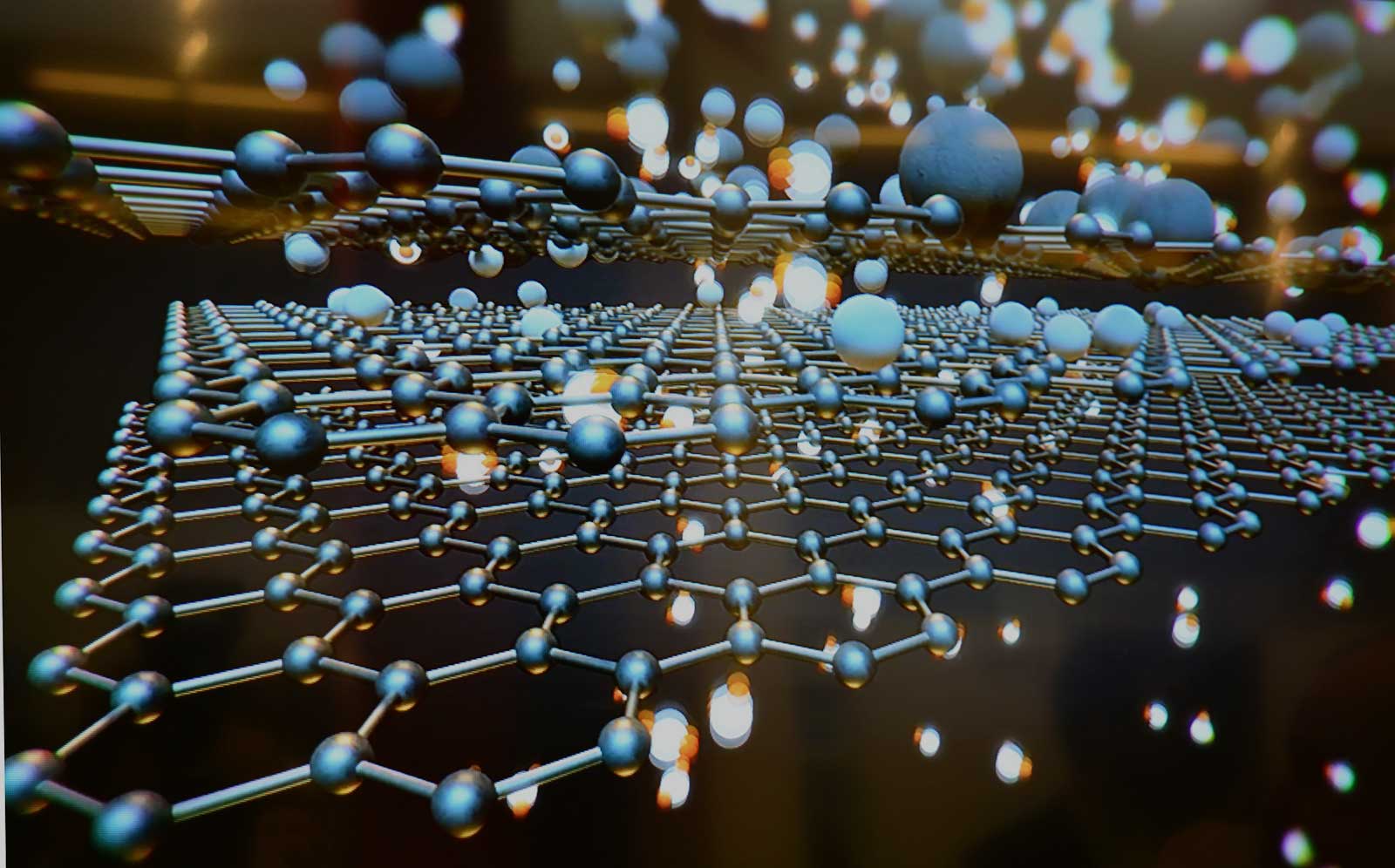

Graphene is a single-atom-thick layer of carbon arranged in a hexagonal lattice, known for its strength, conductivity, flexibility, and barrier performance. Those properties make it useful in everything from energy storage and coatings to sensors and advanced composites.

This guide focuses on what people mean when they search “graphene uses”: practical applications you can buy or deploy today, what’s emerging fast, and what is still mostly research—so you can separate real-world adoption from hype.

Quick Answer: What is graphene used for?

Graphene is used to improve batteries and supercapacitors, strengthen composites, add performance to coatings, enable ultra-sensitive sensors, improve thermal management, and create barrier membranes for filtration and protection. Many “graphene” products use graphene nanoplatelets or graphene oxide blended into other materials rather than a pure sheet of graphene.

At a Glance: Graphene Uses by Readiness Level

Important Note: “Graphene” isn’t one material in products

When you see graphene in real products, it typically means one of these:

- Graphene nanoplatelets (GNP): used as an additive in plastics, rubbers, coatings, and composites.

- Graphene oxide (GO) / reduced GO (rGO): often used in membranes, sensors, coatings, and composite mixes.

- CVD graphene sheets: closer to “pure graphene,” usually reserved for high-end electronics and research due to cost and scaling challenges.

Top Commercial Graphene Uses (You’ll see these in real products)

1) Graphene in coatings and corrosion protection

One of the most practical graphene uses today is improving coatings. When dispersed well, graphene-based additives can reduce permeability to water and oxygen, improving corrosion resistance and durability in harsh environments. This is used in protective paints, marine applications, and industrial coatings where long service life matters.

2) Graphene in polymer composites (plastics and resins)

Graphene nanoplatelets are used as a reinforcing additive in polymers to improve stiffness, strength, and sometimes electrical conductivity. This helps in housings, consumer parts, industrial components, and lightweight structural applications where manufacturers want stronger parts without a major weight penalty.

3) Graphene in rubber and tires

Graphene additives can improve mechanical performance in rubber systems, potentially enhancing wear resistance and supporting better durability. This is why graphene shows up frequently in tire and elastomer research and some commercial mixes.

4) Graphene for thermal management (heat spreading)

Graphene’s thermal conductivity makes it attractive for heat-spreading composites and thermal interface materials. In practice, graphene is blended into a matrix to help move heat away from hotspots in electronics, LED systems, enclosures, and battery-related components.

5) Graphene in conductive inks and EMI shielding

Some formulations use graphene-based materials to create conductive inks or improve electromagnetic interference shielding. These uses often overlap with industrial printing, flexible circuits, and protective electronics packaging.

Emerging Graphene Uses (fast progress, growing real adoption)

6) Graphene sensors (gas, strain, chemical, biosensing)

Graphene’s surface sensitivity can enable sensors that detect tiny changes in environment or strain. This is a major area because sensing often needs extremely low detection limits and fast response times—exactly where graphene can shine when engineered correctly.

7) Graphene membranes for filtration and separation

Graphene-based membranes are studied and developed for filtration and separation—especially where high selectivity and thin barriers matter. Some concepts are already used in specialty filtration, while broader desalination-scale deployment still faces engineering and cost challenges.

8) Graphene in energy storage: batteries and supercapacitors

Graphene-enhanced batteries and supercapacitors are attractive because graphene can support conductive networks, improve power delivery, and sometimes reduce internal resistance. In real products, graphene is typically used as an additive, not as a standalone electrode material.

Mostly Research Graphene Uses (high potential, but not “everyday” yet)

9) Graphene transistors and next-gen computing

Graphene’s high carrier mobility makes it exciting for fast electronics, but “pure graphene” has a key limitation for digital logic: it lacks an intrinsic bandgap. Researchers explore approaches like nanoribbons, stacking, and hybrid structures to address this.

10) Transparent graphene electrodes for displays and solar

Graphene can be ultra-thin and conductive while allowing light to pass, making it a candidate for transparent electrodes. The challenge is achieving consistent, scalable manufacturing with performance that competes economically with established transparent conductors.

11) Advanced biomedical platforms (carefully controlled)

Graphene-based materials are explored for biosensing, drug delivery platforms, and tissue engineering scaffolds, but biomedical adoption requires strict safety validation, repeatability, and regulatory approval—so many exciting results remain research-stage.

What Graphene Is NOT a Magic Fix For

- “Pure graphene in everything” — most real products use graphene as an additive, not as a standalone sheet.

- Instantly 200× stronger products — graphene can improve performance, but results depend heavily on dispersion, bonding, processing, and testing.

- Guaranteed “revolution” timelines — many applications are real, but scaling and cost still matter.

How to choose the right graphene type for a use case

If you’re building content clusters (and improving rankings), this section is powerful because it answers practical intent:

- If it’s coatings/composites: nanoplatelets or GO blends are common.

- If it’s membranes or chemical functionalization: GO/rGO is common.

- If it’s high-end electronics: CVD graphene is typically required.

Conclusion

Graphene uses span multiple industries because the material combines unusual strengths: conductivity, flexibility, strength-to-weight advantages, and barrier performance. The most established graphene applications today are in coatings, composites, and select thermal and conductive formulations. Fast-growing areas include sensors, membranes, and energy storage additives, while “pure graphene electronics” remains one of the most exciting—but still challenging—frontiers.

FAQs

What is graphene mainly used for today?

Today, graphene is mainly used as an additive in coatings and composites, and in some thermal and conductive formulations. These uses are easier to scale than pure-sheet graphene electronics.

What are the top graphene uses in industry?

The top industrial uses include protective coatings, polymer composites, rubber/elastomer reinforcement, thermal management materials, and some conductive inks and shielding applications.

Is graphene used in batteries?

Yes. Graphene is used in some battery and supercapacitor designs—typically as an additive to improve conductivity and power performance rather than as a complete replacement electrode material.

Is graphene safe?

Safety depends on the graphene form, particle size, and exposure route. Industrial handling focuses on dust control, proper PPE, and following workplace safety guidelines. Biomedical applications require much stricter validation.

Why isn’t graphene used everywhere yet?

Scaling, cost, consistent quality, dispersion challenges, and manufacturing repeatability are major reasons. Many applications are real—but mass deployment requires stable supply chains and performance guarantees.

What is the future of graphene?

Near-term growth is likely in coatings, composites, sensors, membranes, and specialized electronics. “Graphene-first” computing devices remain promising but require breakthroughs in device design and scalable production.