Graphene Sensors: How They Work, Uses, and Why They Matter

Graphene sensors represent one of the most advanced sensing technologies developed from two-dimensional materials. Their extreme sensitivity, fast response time, and flexibility are reshaping how physical, chemical, and biological signals are detected.

This article explains what graphene sensors are, how they function at the atomic level, where they are used today, and why they are considered transformative across science, medicine, and industry.

What Is a Graphene Sensor?

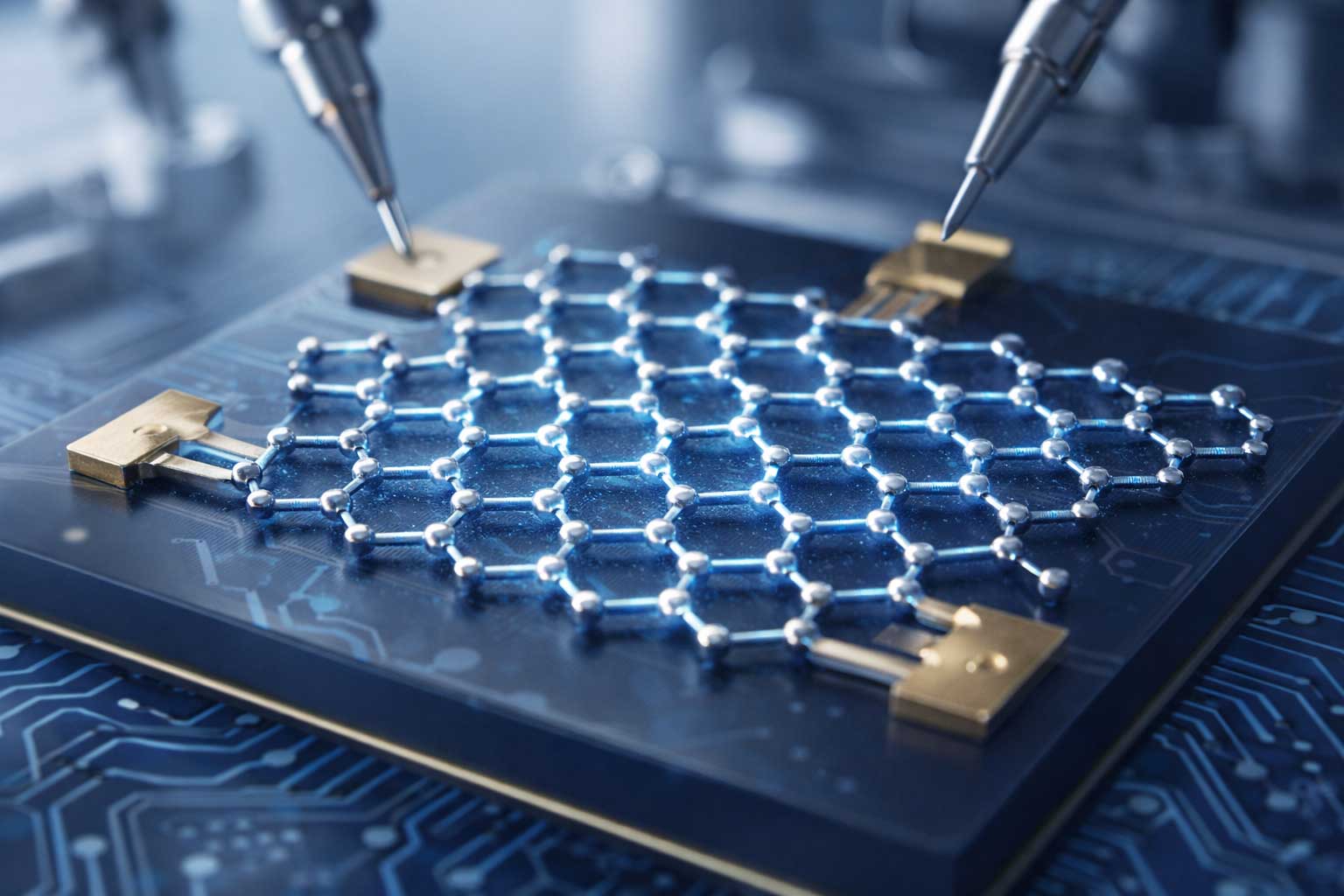

A graphene sensor is a detection device that uses graphene or graphene-based materials as the active sensing element. The sensor operates by translating minute physical or chemical changes—such as gas exposure, pressure, strain, or biological interaction—into measurable electrical signals.

Unlike conventional sensors that rely on bulk materials, graphene sensors leverage surface-level interactions. Because nearly all atoms in graphene are exposed, even the smallest environmental change can significantly alter its electrical behavior.

How Graphene Sensors Work

Graphene sensors function by monitoring changes in electrical conductivity, resistance, or capacitance when external stimuli interact with the graphene surface.

When molecules, pressure, temperature shifts, or biological agents come into contact with graphene, they disrupt electron flow within the material. These disruptions are detected instantly as signal changes, allowing the sensor to respond with exceptional sensitivity.

This mechanism enables detection at extremely low concentrations—often down to parts per billion or even single-molecule levels in laboratory settings.

Types of Graphene Sensors

Gas Sensors

Graphene gas sensors detect gases such as hydrogen, ammonia, nitrogen dioxide, and volatile organic compounds. Adsorbed gas molecules alter charge carrier density, producing measurable electrical shifts.

Pressure and Strain Sensors

Flexible graphene films change resistance when stretched or compressed, making them ideal for pressure, motion, and structural monitoring applications.

Biosensors

Graphene biosensors identify biological molecules such as glucose, DNA, proteins, and viruses. Functionalized graphene surfaces bind selectively to target biomolecules, enabling rapid medical diagnostics.

Temperature Sensors

Changes in temperature affect graphene’s electrical properties, allowing precise thermal monitoring in compact and flexible devices.

Chemical and Liquid Sensors

Graphene sensors can analyze pH, ion concentration, and chemical composition in liquids, making them valuable for water quality monitoring and industrial process control.

Key Advantages of Graphene Sensors

- Ultra-high sensitivity: Detects extremely small changes

- Fast response time: Near-instant signal conversion

- Low power consumption: Suitable for portable devices

- Mechanical flexibility: Enables wearable and bendable sensors

- Miniaturization: Ideal for compact electronics

These advantages allow graphene sensors to outperform many traditional silicon-based and metal-oxide sensors in specialized applications.

Applications and Use Cases

- Medical diagnostics and biosensing

- Wearable health monitoring devices

- Environmental air and water monitoring

- Industrial safety and gas leak detection

- Smart infrastructure and structural monitoring

- Automotive and aerospace sensing systems

- Internet of Things (IoT) devices

Graphene sensors are particularly valuable where real-time monitoring, flexibility, and sensitivity are critical.

Production and Manufacturing Challenges

Despite their promise, graphene sensors face manufacturing challenges. Producing consistent, high-quality graphene at scale remains complex, and sensor performance can vary depending on material quality and fabrication methods.

Integration with existing electronics, long-term stability, and environmental robustness are ongoing engineering challenges. Research continues to focus on improving reliability and lowering production costs.

Safety and Environmental Considerations

Graphene sensors used in consumer and medical devices typically embed graphene within solid substrates, minimizing exposure risks. Health concerns primarily apply to airborne graphene nanoparticles during manufacturing, not finished sensor products.

Environmentally, graphene sensors may reduce material usage and energy consumption compared to conventional sensor technologies, offering potential sustainability benefits.

Future Outlook

Graphene sensors are expected to play a central role in next-generation electronics, healthcare diagnostics, and smart systems. Advances in large-scale manufacturing, surface functionalization, and integration will accelerate commercial adoption.

As sensor networks expand across cities, homes, and bodies, graphene’s ability to detect the nearly undetectable positions it as a foundational material for the future of sensing technology.

Frequently Asked Questions

What makes graphene sensors more sensitive than traditional sensors?

Because graphene is atomically thin, nearly all atoms interact with the environment, allowing extremely small changes to produce detectable electrical signals.

Are graphene sensors already used commercially?

Yes. Graphene sensors are used in research instruments, industrial monitoring, and emerging medical devices, with broader consumer adoption underway.

Can graphene sensors be worn on the body?

Yes. Their flexibility and low power requirements make them ideal for wearable health and fitness sensors.

Do graphene sensors require high power?

No. Graphene sensors typically operate at low voltages and consume less power than many conventional sensor types.

What limits graphene sensor adoption?

Manufacturing consistency, cost, and long-term stability remain the main barriers, though rapid progress is being made.

Leave A Comment