What Are Graphene Sleeves

Graphene sleeves are advanced protective and performance-enhancing covers or wraps made with graphene-enhanced materials. They combine lightweight strength, thermal regulation, conductivity, and durability into a versatile sleeve solution.

This article explains what graphene sleeves are, how they’re made, their key properties, applications across different industries, advantages and limitations, safety and environmental factors, and future outlook.

Definition: What Are Graphene Sleeves?

A graphene sleeve is a tubular or wrap-style protective material enhanced with graphene or graphene-related additives. Graphene — a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice — is exceptionally strong, lightweight, thermally conductive, and electrically conductive. When incorporated into fabrics or polymers, it elevates the performance of sleeves used for protection, compression, insulation, or technical functions.

Composition and Structure

Graphene sleeves are typically produced by embedding graphene particles, graphene oxide, or reduced graphene oxide into fibers or coating existing sleeve materials. Manufacturing methods vary but often include:

- Graphene-enhanced yarn spinning: Integrating graphene into synthetic or natural fiber blends.

- Surface coating: Applying graphene formulations onto textiles.

- Composite layering: Sandwiching graphene layers within polymer matrices.

The result is a flexible sleeve that maintains breathability while offering enhanced mechanical and functional properties compared to traditional materials like nylon, polyester, neoprene, or cotton blends.

Key Properties of Graphene Sleeves

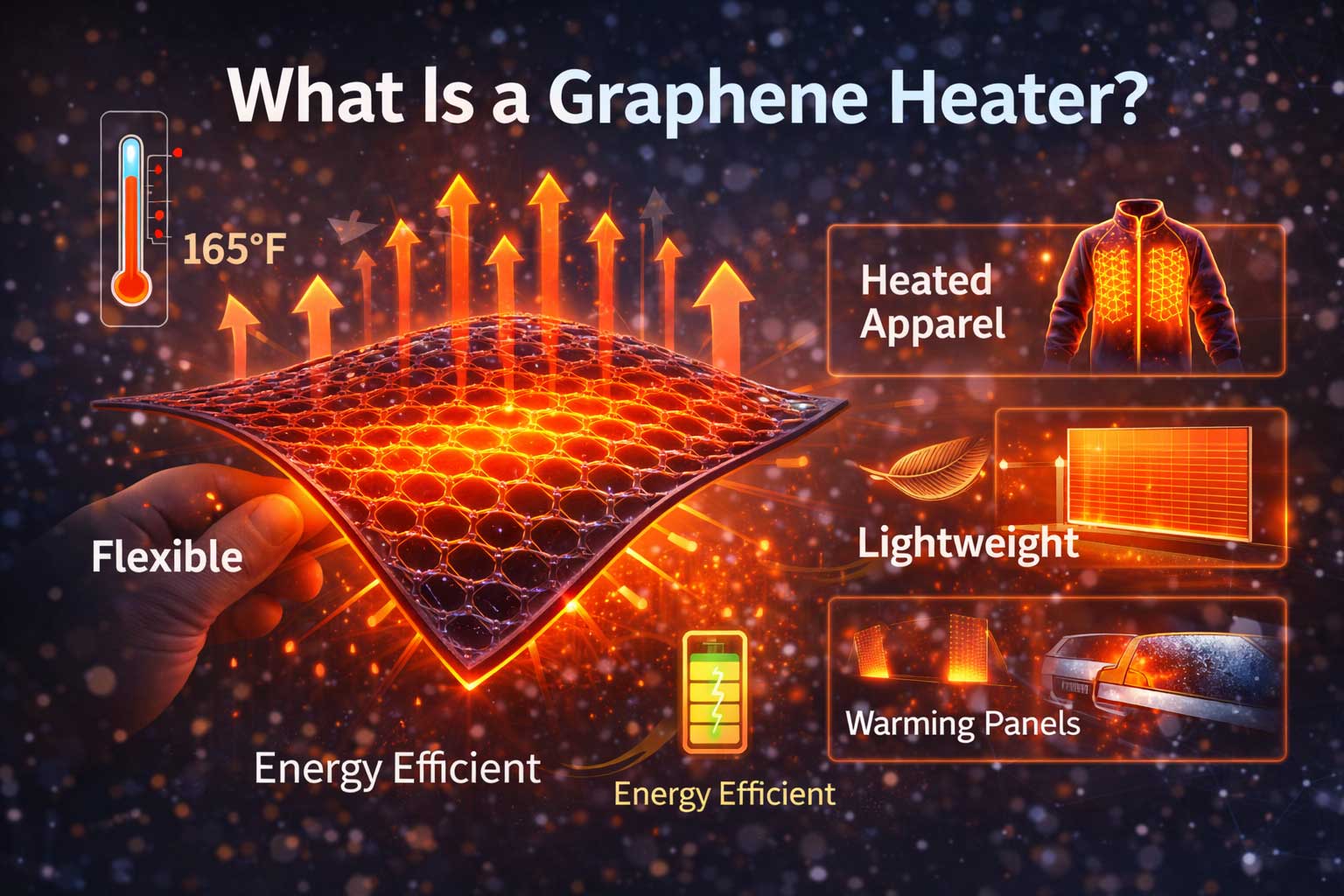

Graphene sleeves exhibit several standout properties that differentiate them from conventional sleeves:

- High strength and durability: Graphene’s intrinsic strength increases tear and abrasion resistance.

- Thermal regulation: Excellent thermal conductivity helps disperse heat and improve comfort.

- Lightweight flexibility: Maintains freedom of movement with minimal added weight.

- Electrical conductivity: Enables potential EMI shielding or smart textile integration.

- Antimicrobial performance: Natural bacterial resistance without chemical treatments.

Applications and Use Cases

Graphene sleeves are used across diverse industries. Key applications include:

Sports and Activewear

Athletes and fitness users benefit from graphene sleeves for compression and muscle support. Enhanced thermal regulation and antimicrobial properties improve comfort and hygiene during prolonged use. Common products include arm sleeves, calf sleeves, knee supports, and elbow compression wraps.

Medical and Therapeutic

In rehabilitation and physical therapy, graphene sleeves assist with support, mild compression, and warmth management. Their breathability and durability make them suitable for repeated clinical or home use.

Industrial Protection

Graphene sleeves are adapted for industrial applications such as protective cable coverings, heat-resistant wraps, and abrasion protection for hoses or pipes. Thermal conductivity and strength are especially valuable in high-temperature or high-wear environments.

Electronics and Technical Textiles

Due to graphene’s conductivity, specialized sleeves can provide electromagnetic interference (EMI) shielding or serve in wearable electronics, sensors, and smart textile interfaces.

Advantages

Graphene sleeves offer several compelling advantages:

- Enhanced durability: Graphene reinforcement increases lifespan over traditional sleeves.

- Improved comfort: Better heat dispersion and moisture management.

- Lightweight performance: Increased strength without significant weight gain.

- Multifunctionality: Potential for thermal, electrical, and antimicrobial benefits in one product.

Limitations and Challenges

Despite their promise, graphene sleeves also face limitations:

- Cost: Graphene additives raise material expenses compared to standard textiles.

- Scale and consistency: Uniformly dispersing graphene at commercial volumes remains a manufacturing challenge.

- Performance variability: Properties depend heavily on graphene quality and integration technique.

Safety, Ethical, and Environmental Considerations

Graphene materials must be manufactured and handled with care to avoid inhalation of fine particulates. When embedded in textiles, graphene is generally stable and low-risk for end users. Companies should ensure responsible sourcing and disposal of graphene-enhanced fabrics to minimize environmental impacts.

Future Outlook

Research and development continue to expand the capabilities of graphene sleeves. Improvements in scalable manufacturing, cost reduction, and multifunctional performance could broaden adoption across consumer, medical, and industrial markets. Integration with smart technologies — such as sensors and adaptive textiles — is also a key growth avenue.

Frequently Asked Questions

What makes graphene sleeves better than regular sleeves?

Graphene sleeves can be stronger, more thermally conductive, antimicrobial, and more durable than sleeves made only from traditional fibers.

Are graphene sleeves safe to use on skin?

When graphene is embedded within textiles, the material is generally safe and non-irritating for skin contact. Quality control and proper manufacturing are important.

Can graphene sleeves help with muscle recovery?

Graphene compression sleeves may improve comfort and circulation, which can support recovery, though results vary by individual and use case.

Do graphene sleeves conduct electricity?

Graphene’s conductivity can be leveraged in specific designs, especially for technical or EMI shielding applications.

Are graphene sleeves environmentally friendly?

Environmental friendliness depends on manufacturing and end-of-life disposal practices. Graphene materials themselves are carbon-based, but responsible processes are important.